One of the best parts of our job as storage solutions providers is watching our customers’ businesses grow. We’ve been with some of our customers from their start-up days and are proud to continue to be their go-to source. In the last year, we completed two projects for one of those businesses. See how we helped them overcome their storage and processing challenges.

Spotlight Overview

- Who – Growing health and performance nutrition company

- What – Finished goods storage

- Size – Each warehouse approximately 40,000 sq. ft.

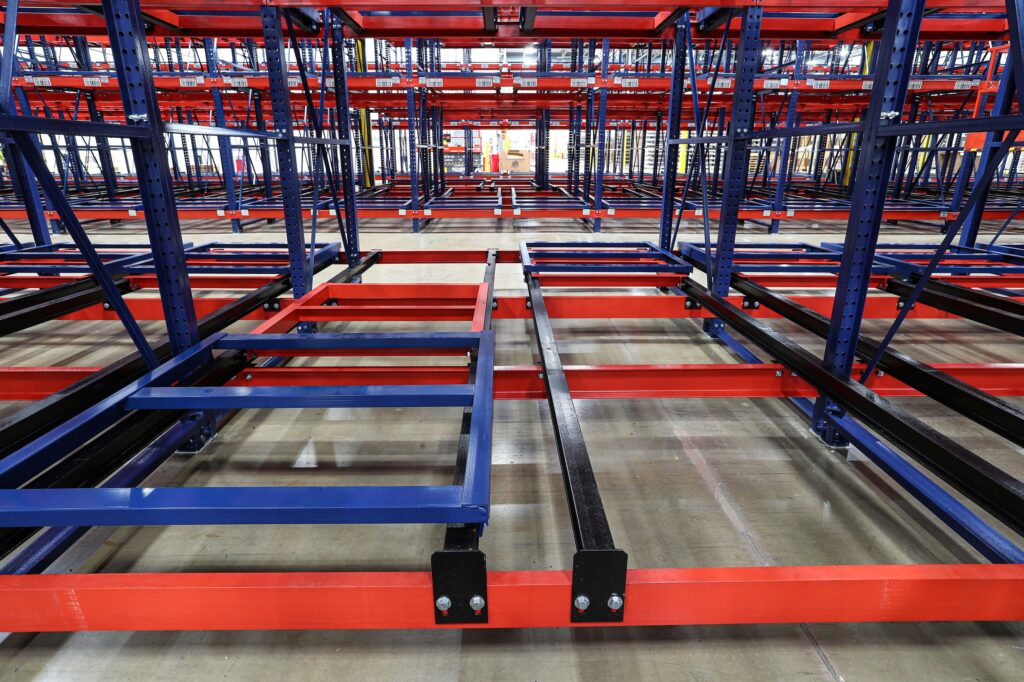

- Storage Systems – Structural drive-in & push-back rack and reprofiled roll-formed selective

- Considerations –

- One temperature-controlled facility

- Strict adherence to cleanliness onsite to meet food warehouse requirements

Project A – Goal: Create a storage solution to fit the specs of a new inventory mix and improve storage efficiency.

Customer Challenge: The customer faced a common challenge. Their new product mix specs did not fit in the existing selective racking system. Floor stacking only allowed for 2-high loads, which was insufficient.

Apex Solution: The Apex team designed a multi-system approach to tackle the storage challenge. Drive-in combined with 3-levels of push-back rack above provides the storage capacity required in an orderly, accessible, and condensed footprint. Apex also reprofiled the existing selective rack around the perimeter of the room to accommodate the new product mix.

- Push-back pallet rack (2-deep and 3-deep sections)

- Ground-level drive-in pallet rack with room for double stacking

- Single rows of roll-formed selective reprofiled for the new inventory specs

The Results: Greater storage capacity, efficient use of space, and easily accessible SKUs to improve pick speed and accuracy.

|

|

Project B – Goal: Achieve more efficient picking/packing with orderly finished goods storage.

Customer challenge: Their current floor stacking setup could not accommodate existing storage or order fulfillment goals.

Apex Solution: Apex created two push-back racking storage systems to store 65% of the finished goods inventory, leaving approximately 35% of the lighter & taller loads for floor stacking.

- Push-back rack – 3-pallets deep, 4-levels high

- Puh-back rack – 3-pallets deep, 5-levels

- Bulk stack – lighter & taller loads

The Results: The new storage solution increased storage capacity by approximately 40%. It also helped the customer maintain the level of cleanliness that they require by getting the inventory off the floor and into the racks.

Contact the Apex team to discuss your warehouse challenges. Our team is experienced and equipped to design and engineer your storage rack solutions and install them with minimal disruption to your day-to-day operations. We look forward to adding your business to our growing list of long-term customers.

|

|