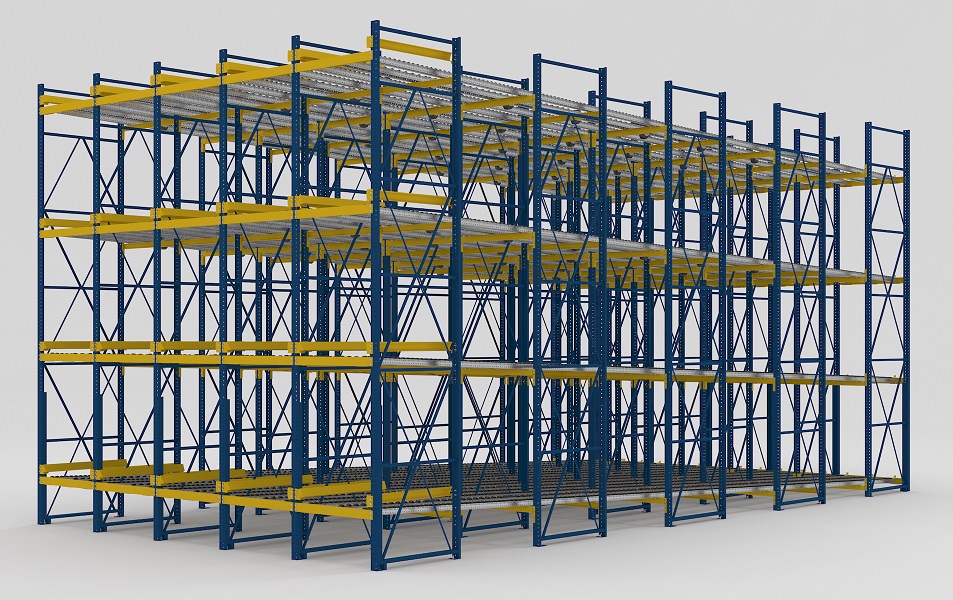

Dynamic, High-Density Pallet Flow Storage Racking

Pallet flow rack provides superior storage density over all other rack systems with a First-In/First-Out (FIFO) inventory flow. It is best suited for inventory with a limited number of high-volume SKUs. The system design is tightly configured, packing in a high number of pallets in a condensed space. Flow lanes have wheeled or roller rails installed on a slight pitch to automatically flow pallets from the load side to the pick aisle, helping you minimize travel time and associated labor and equipment costs.

Save with Pallet Flow Rack

Save with Pallet Flow Rack

- Double storage capacity over static rack systems

- Save up to 75% in labor & equipment costs

- Reduce utility expenses with condensed storage

Pallet flow racking is also often beneficial for ergonomic case picking. The application provides dense reserve storage and an automatically replenished pick face when the empty pallet is removed. Speak with the Apex systems design experts for custom gravity flow rack applications to enhance your team’s productivity.

Advantages | Considerations

- Double the capacity vs. conventional pallet rack storage

- More productive – less travel time between aisles

- Lane depth 2- to 10-pallets deep

- FIFO inventory rotation – ideal for dated goods

- Higher cost per pallet position

- Additional height required per level

How Does Pallet Flow Rack Work?

Pallet flow rack is most often configured using opposite aisles for pallet loading and extraction. This system design supports FIFO inventory rotation.

- The forklift operator loads pallets from the rear of the system.

- Pallets flow forward to the opposite aisle.

- The forklift extracts the pallet at the pick face.

- Rear pallets begin flowing automatically to replenish the empty pallet position

Rails are easily mounted to standard pallet racking systems; however, choosing the best pallet flow lane design will depend heavily on inventory specs and pallet material.

What are your pallet & inventory specs?

Standard GMA-style wooden pallets are most often suited for wheeled pallet flow rails.

Plastic pallets, metal containers, footed pallets, and crates typically do better in roller pallet flow.

The goal is sufficient contact between the flow rails and the bottom of the pallet, container, or crate.

Call Apex to work with an experienced gravity flow rack design team. Let's deliver the productivity and space-saving goals that you need to compete.

Watch Productivity in Action with Pallet Flow Rack

Watch our short animated pallet flow simulation and see how this space-saving, dynamic storage solution will maximize your warehouse space while increasing picking efficiency.

Does pallet flow look like a good fit for your warehousing needs? Give the Apex team a call to discuss the best way to maximize your warehouse space and meet faster turn rate objectives.

The Solutions You Need to boost warehouse productivity

Automation Solutions

Warehouse automation for optimal efficiency

Warehouse Storage Equipment

Pallet racking, warehouse design & installation

Rack Inspection & Repair

Pallet rack inspection and repair services

Quick Ship Inventory

New and used pallet rack & components & accessories

Contact Us To Get Started

Fill out the form below or call us at 331-263-6154 to speak with an expert.