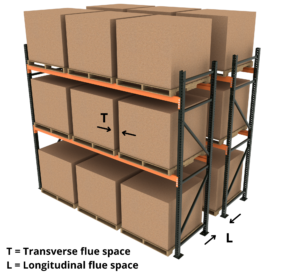

According to the National Fire Protection Association (NFPA), there are two types of flue spaces to consider when designing a pallet racking storage system for your warehouse: Transverse and Longitudinal Flue Spaces. See example below.

According to the National Fire Protection Association (NFPA), there are two types of flue spaces to consider when designing a pallet racking storage system for your warehouse: Transverse and Longitudinal Flue Spaces. See example below.

- Transverse Flue Space: Orientating yourself towards the racking face, this is the space between the product being stored parallel to the direction of loading.

- Longitudinal Flue Space: Orientating yourself to the end of the row of racking, this is the space between each back-to-back row of pallet rack perpendicular to the direction of loading.

NFPA defines flue space (Transverse or Longitudinal) as clear vertical lines of sight from the floor up to the ceiling within rack storage systems. In the event of a fire, these flue spaces allow fires to vent upward from floor to ceiling so that it can be mitigated properly by the sprinkler system. By enabling the fire to vent upward, it will contain the risk to a more confined space rather than the risk spreading across multiple bays or rows of pallet racking.

Transverse Flue Space and What It Means for You

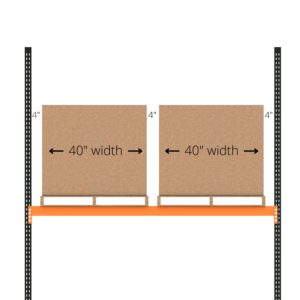

Most storage systems have been designed with even spacing between commodities and uprights. As shown below, a 92” beam would use a 4” transverse flue spacing throughout, assuming a standard 40” wide load is being stored.

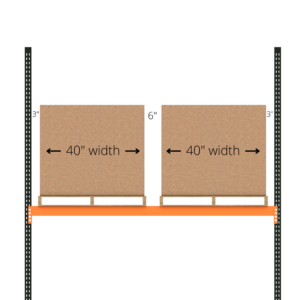

According to the NFPA, there must be a 6” transverse flue space between loads within a rack structure. A 92” long load beam can still work, in theory. However, the loads will need to be situated as shown below.

It is important to note that, in most cases, a standard bay opening of 96” is used. The idea is still the same, but you would see your transverse flue space increase 5”, 6”, and 5” respectively.

Solutions for Transverse Flue Space

|

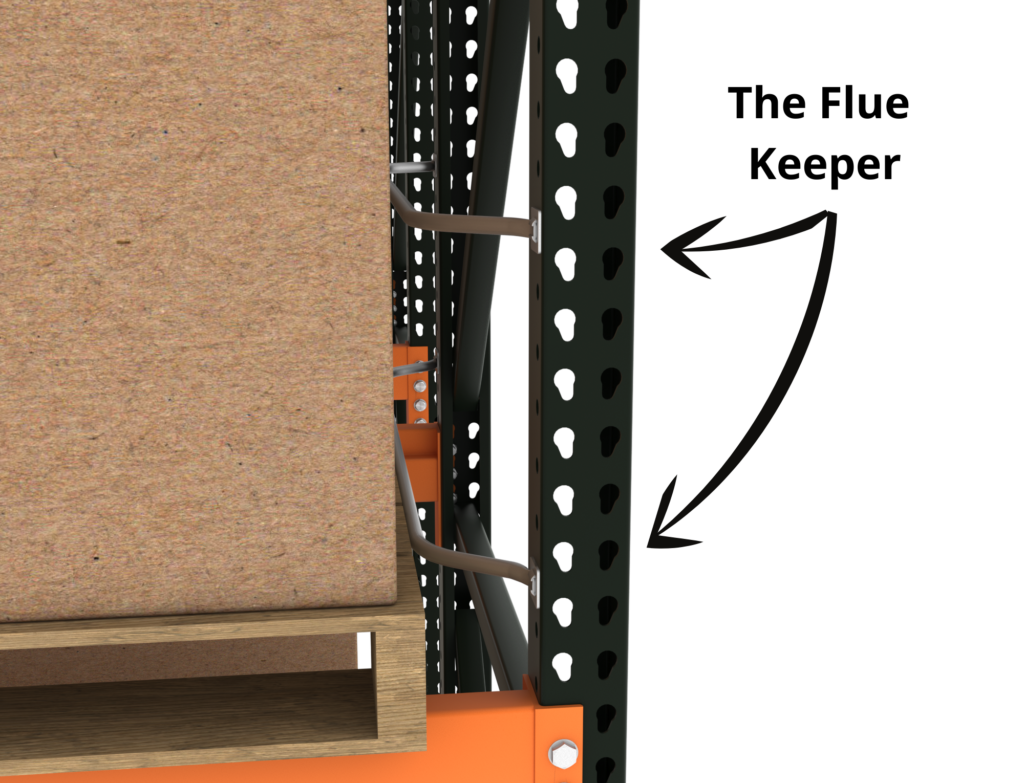

The Flue Keeper was designed to keep boxes and pallets from encroaching into the transverse flue space in order to improve sprinkler penetration to products within the pallet rack structure. These flue stops meet NFPA standards. |

|

This snap-in divider is constructed of heavy-duty steel wire with clips that fasten to traditional wire mesh decking. These types of dividers are typically used in a case picking operation but can be used as a visual aid to forklift operators when loading conventional sized pallets into a racking system. |

Designing and Maintaining a Longitudinal Flue Space

When designing back-to-back rows of racking that will utilize a longitudinal flue space, it is always best to check with local city ordinances with regard to fire safety regulations. NFPA dictates a minimum longitudinal flue space of 6” to allow fire ventilation along with water penetration from the sprinkler system above. This design is also driven by the commodity that is being stored. For example, if a commodity that is highly combustible is being stored in the racking, the longitudinal flue space may be required to be larger than the typical standard to accommodate in-rack sprinklers.

Other driving factors are the depth of your loads. The common pallet/load depth is 48” deep. However, if longer pallets/loads are being stored, an alternative longitudinal flue spacing may be required to maintain a standard operating aisle on the front end of the system.

Well-designed storage systems allow the pallet to overhang over the back beam in a back-to-back row of racking. While spacing may be contingent on local municipal code, as mentioned above, the most common space is 6” between loads. The most common scenario is using a 42” deep upright with 48” deep pallets/loads. In this scenario, the pallet will overhang 3” off the front and rear beam on both sides of a back-to-back row. Using simple arithmetic, 3” overhang x (2) pallets (front and rear) + 6” Longitudinal Flue = 12” spacing between rows.

Solutions for Longitudinal Flue Space

|

Row spacers are commonly used as an installation tool to maintain a designed Longitudinal Flue Space. They are common in increments of 2”, but unique sizes can be manufactured. Various manufacturers have different requirements for the number of row spacers used but the most common is (1) row spacer per 10’-0” of frame height. |

|

Load stop beams are effective in maintaining a standard Longitudinal Flue Space as it prevents the operator from physically placing the pallet further in the system than the design intended. Manufacturers can offer these load stop beams with various offsets based on the requirement. |

Maintaining the transverse and longitudinal flue spaces is critical to the safety of your product and staff. Several studies conducted by the NFPA has shown a failure in sprinkler systems in the event of a fire when these flue spaces are obstructed or designed poorly.