Meet Accelerated Case & Each Picking Output

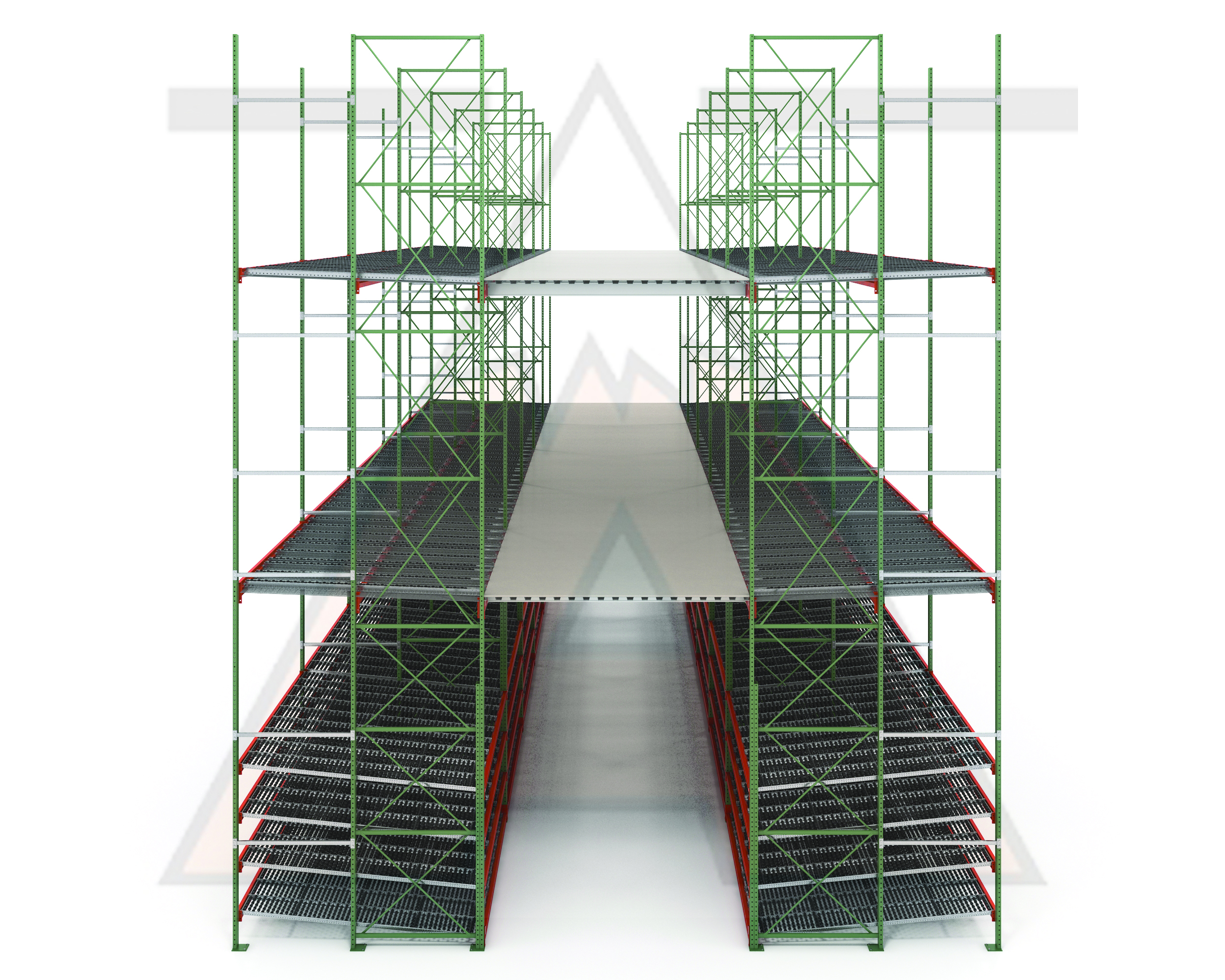

Pick modules - it's where the strategic integration of storage rack, shelving, and conveyor systems come together to maximize warehouse space and enhance order picking performance. The Apex team has extensive experience in pick module design and installation. We've created relatively simple pick tunnels to complex multi-level operations with handpicking and automation working seamlessly together to deliver results. Each pick module is customized to the facility layout and business goals.

Most pick modules include a combination of gravity flow rack and shelving to store product in a way that separates each pick slot but allows storage for several pieces per slot. Order pickers select items from ergonomically positioned levels and place them on conveyors for packing or mobile carts equipped with totes for batch processing.

Common Pick Modules Applications

- E-commerce

- 3PL

- Retail

- Kitting

- Beverage

- Beer, wine, spirits

The makeup of the storage types and configuration in your pick module is based on the number of SKUs, the volume, and the pick rate goals. Your inventory specs will also play a role with larger, heavier weighted items positioned within easy reach to minimize worker strain.

3-Tier Mezzanine Pick Module

Aerial View - 3rd-Tier Top Left

Boost Pick Activity with Rack that Rolls

Building a Pick Module

- Carton flow rack

- Pallet flow rack

- Industrial shelving

- Vertical pocket storage

- Conveyor

- Sortation conveyor

Pick modules areas often include gravity flow storage such as carton flow and/or pallet flow. These dynamic systems use wheels and rollers to flow inventory from the rear load aisle to the pick aisle. As workers pick items, inventory flows forward, automatically replenishing the pick face and keeping your team picking, not waiting. Reserve storage is often located nearby in adjacent lanes or in storage levels above the pick area, which keeps vehicles out of the way and improves worker safety and productivity.

Carton flow is best for medium-turn inventory. Slower movers can be stored in less expensive shelving. There are a lot of shelving systems to choose from that deliver abundant SKU storage in a small footprint, including hanging systems and easily configurable industrial shelving.

A well-designed system combines technology with conveyor and sortation systems to move the product from in-processing through order fulfillment. Full pallets transferred from push-back, pallet flow, or pallet rack reserve storage break down into cartons and pieces. Items are then loaded into specially designed pick-areas to complete staging for order fulfillment. If it’s part of a pick module, the Apex team has worked with it, and we will work with you to combine the products that best fit your needs to create the most cost-effective order picking operation for your business.

What Can You Expect from an Apex Pick Module?

Design your pick module for optimal efficiency.

- Improved space utilization– save up to 50% vs. selective rack

- Reduce labor costs – less travel time

- Increase pick rates – easy access, consolidated SKUs

- Increase pick locations - store more in less space

- Configurable with automation to improve pick rates & accuracy

Apex Companies is a full-service material handling family of businesses that work seamlessly to support our customer needs anywhere along the project process. From consulting, design, and engineering, to automation services and installation, to professional rack audit and rack repair.

We are a dealer for CLARK, BYD, and Big Joe forklifts for the Chicago metro area and provide dealer-certified service and parts.

All the expert support you need, all in one place. How can the Apex team help you today? Give us a call for a free consultation and begin the journey to order processing optimization.

Check out a few of our recent pick module projects:

The Solutions You Need to boost warehouse productivity

Automation Solutions

Warehouse automation for optimal efficiency

Warehouse Storage Equipment

Pallet racking, warehouse design & installation

Rack Inspection & Repair

Pallet rack inspection and repair services

Quick Ship Inventory

New and used pallet rack & components & accessories

Contact Us To Get Started

Fill out the form below or call us at 331-263-6154 to speak with an expert.